Why do electronic projects not work? It has too many reasons. One of the most reasons that I found often is bad soldering. Here is a tip on how to solder circuit boards and wires.

It’s challenging and fun. To practice electronics soldering skills.

At first, I didn’t know any techniques. It makes me a waste of time. I don’t want you to be like me.

Good soldering

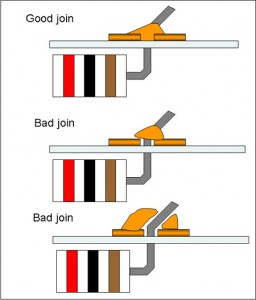

When I was a beginner. Most projects do not work in first. Because my solder joint is bad.

Look at the image below.

It may cause an electric current does not flow through the circuit devices. Or sometimes, I soldered too much until a short circuit. These are all the reasons the project is not working.

Good soldering requires great skill. Experience and Which has how as follows.

Let’s get started.

Do you have important tools?

You need to use a great tool to do that.

soldering iron

Cr Photo: Weller Store

To begin with, you should one of a good soldering iron.

or

Cr: Photo Plusivo Store

To reduce problems in the long run. Your time is worth more than the money spent. You should use this one can adjust watts or temperature. The temperature regulation will reduce destroying on surface mount SMD devices.

While working a soldering iron has a temperature at tip very hot—about 300°C.

It is enough to melt tin and lead.

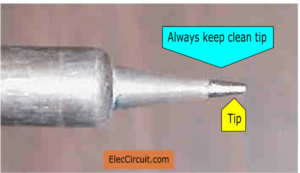

Importance—you need to always keep the clean iron tip. Wipe the tip to clean on a damp sponge or Soldering Iron Cleaning Sponge.

Sold wire

Second, You need to use a good solder wire. This is a soft metal wire, usually mixed with tin and lead.

Normally we always buy big leads because worthy than small ones. My son buys new solder; DIA: 0.8mm 1LB TIN/LEAD 60/40. But He does not like it because too heavy and difficult to use. See above!

When the heat of the soldering iron to metal, zinc, copper surface. They get heat. Then, these surfaces are also hot enough to melt the solder wiring to cover these surfaces. Important, they should be clean!

Special soldering wire exists for Electronics work, which comes with an inner core of Flux or Rosin.

How to solder on circuit board

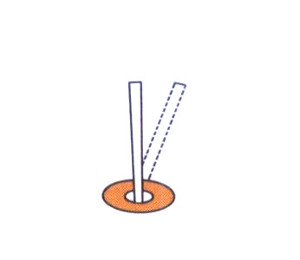

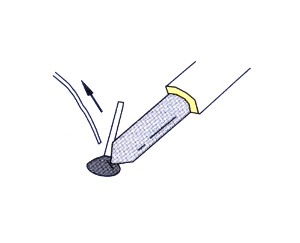

First, you should bend slightly device’s leg.

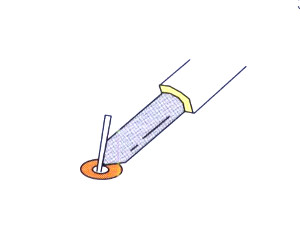

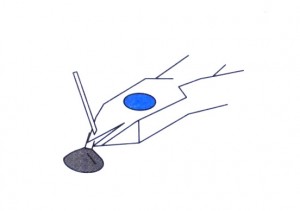

2. Bring a soldering iron tip to touch the device’s leg and pad for about 3-5 seconds. To absorbs heating from the tip of the iron to them at approximately 300 ° C.

In normal use, you should set watts at 20 watts for a beginner because of not too hot when used for semiconductor parts. My friends used this soldering iron it can set watts for all parts

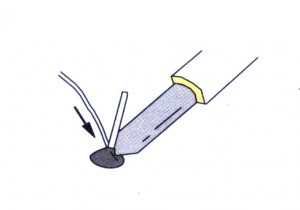

3. Now the leg of the component will be very hot as an iron tip. So you can feed a lead solder to touch the component’s leg until the solder melts the full pad.

Do not feed solder to the tip of the iron.

4. Then pull solder out, and still tip at solder joint for 3 seconds.

5. You can complete the soldering.

6. Use wire cutters to cut each wire just above the joint, be carefully cut into the solder joint.

How to choose a wire cutter

You should Soft Wire Cutter because you often use them. It should be made of Hardened Carbon Steel Construction.

Also, it has An internal spring that returns the tool to the open position, reducing operator fatigue.

Warnings Always wear safety glasses. While cutting the wire to the electronic device Sometimes it splashes far and is very heavy.

How to solder wires together

The beginner asks me how to solder wires. It is also easy.

Helping hand and Smoke Absorbing Fan

Sometimes you need to use a helping tool. It helps the wiring and the circuit board is easier.

Normally when we solder several electronics projects, always difficult

I see on the internet people like to use a helping hand tool as below.

When we are older, our eyes are not good. Soldering electronic components are very difficult since the device is very small.

So we would like to add the magnifying glass to clearly increase to see the equipment up.

Your health is the most important. Let’s use Smoke Absorber.

Features:

- Remove noxious fumes quickly, safely, and efficiently.

- The fan is fully adjustable, quiet, and long service life.

- Portable and desktop design, easy to place and move low noise, and long life service.

- The replaceable filter is made of urethane foam with refined, activated, high absorption carbon.

I love electronics. I have been learning about them through creating simple electronic circuits or small projects. And now I am also having my children do the same. Nevertheless, I hope you found the experiences we shared on this site useful and fulfilling.

thank you very much to teach how to soldering

Hi, Harun from Kenya I have learned much on electronic thro’ quick learning I’m now withdrawing mentality that electronic is complicated keep up guys

Hello Harun,

Thanks for your feedback.

If you want to learn what please tell us.

Best,

Hi,mujtaba

Thanks for your feedback.

thankes to teach

thankes to teach of this topic

Hi kumar vinod,

Thanks for your feedback.

nice amd informativeeeeeee…….thanks

Hi Jawad Ahmad

Thanks for your feedback.

one thing you forgot is that after soldering the spot should be shiney. Adull or blackened spot means a weak joint. With all due respect.

Thanks for your feedback.

About a year now that ive been wanting to learn how components work but at first glace at any diagram of any kind makes me go cross eyeded for a sec any suggestions where or how to get started

Thank You For a Wonderful Presentation!!!!!

Publish Bet.tv books on electionic video conferencing build with circuits boards ?

Thanks it’s very use full